Using the principle of “thermal oxidation,” a combustion process, the contaminants within the polluted exhaust gas react with oxygen in a temperature controlled environment. The chemical oxidation reaction destroys the contaminants in the polluted exhaust gas before discharging it back into the atmosphere. What is released is an innocuous emission of CO2, water vapor, and heat.

PCC Thermal Oxidizers

PCC thermal oxidizers operate on the principle mentioned above, which is thermally promoting an oxidation reaction between the pollutant compound in the exhaust gas and the available oxygen. We supply two types of the Thermal Oxidizers: direct fired (afterburner) and recuperative thermal oxidizers.

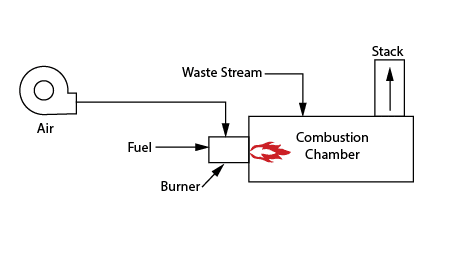

Direct Fired Thermal Oxidizer

The simplest type of thermal oxidizer, it does not include any type of heat recovery system to recover a portion of the waste heat generated by the combustion process.

A direct fired thermal oxidizer system typically includes:

- Burner

- Combustion chamber

- Blower

- Air/fuel train

- Instrumentation and controls

- Exhaust stack

Typically less expensive than other types of thermal oxidizers, direct fired thermal oxidizers will incur higher operating cost (fuel use) for waste streams that are endothermic.

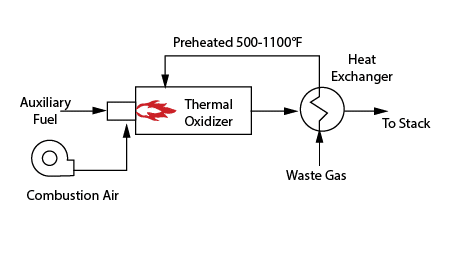

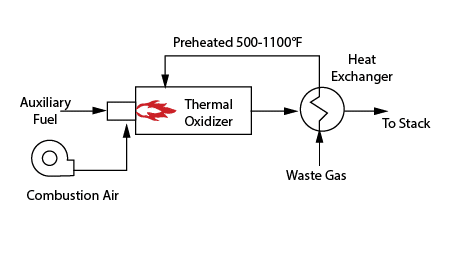

Recuperative Thermal Oxidizer (Afterburner)

This system is a direct fired thermal oxidizer with heat recovery added at the discharge end of the combustion chamber.

Downstream heat recovery equipment uses the available heat produced within the thermal oxidizer combustion chamber to reduce auxiliary fuel consumption, produce steam, heat a process air stream, or heat a liquid

stream. A recuperative thermal oxidizer system can have a single heat recovery device or multiple heat recovery devices.

In addition to the recuperative thermal oxidizer systems shown above, a recuperative thermal oxidizer can incorporate:

- Combustion air preheat to conserve fuel

- Other heat recover equipment such as a hot oil heater, hot water economizer, or asphalt heater

Recuperative thermal oxidizers can treat multiple gaseous and liquid waste streams that are endothermic and/or exothermic.

Applications

Thermal oxidizer applications: custom designed and proven.

Our core engineering staff is experienced in process engineering, material selection, refractory design, structural design, and controls and instrumentation. With degrees in various engineering disciplines, our Professional Engineers (P.E.) are also registered in several states.

We’ve custom designed more than 1,000 systems for Fortune 500 companies of all sizes– and we have an excellent track record for performance and reliability. Here are some of our typical applications.

- Acrylonitrile

- Terephthalic Acid

- Butanediol

- Mercaptanes

- Low BTU Gases

- VOC’s

- Waste Oils

- Butyl Chloride

- Phosphine

- Hydrogen Cyanide

- Toluene

- Benzene

- Halogenated Hydrocarbons

- Trichloropropene

- Maleic Anhydride

- Dibutyl Phthalate

- Trifluoroacetic Acid

- Chlorinated Hydrocarbons

What our customers are saying...

"PCC... The best-kept secret in the industry."

— Rohm & Haas

"PCC works like a well-oiled machine."

— Louisiana Pigments Company

"We would not be where we are today without the engineering knowledge and efforts, quality of construction, professionalism, and cooperation of your first-class organization."

— Montauk Energy Capital

"PCC's commitment to safety and quality allow completion ahead of schedule, under budget, and safely."

—

"PCC's desire to deliver a quality product was apparent throughout all phases of our project, and PCC's overall gas combustion experience resulted in a robust and reliable operating unit."

—

"We are very pleased that it was commissioned five weeks earlier than the contract completion date."

—

"PCC was absolutely on time with delivery of our thermal oxidizer... I was quite impressed. All the units we bought from PCC run flawlessly, even after 10 years. We can't calculate a MTBF, because there have been no failures."

—